There are currently no 100% H2-CHP installations in most European countries. There are none in the Canary Islands. An alternative are 100% H2 boilers, but they too at R&I stage. EU funded BIG HIT combined 12 5kW domestic H2 boilers to heat 2 schools. Progress is being made on blend-certified condensing boilers (typically 20% H2 with natural gas) which will eventually be replaced by pure hydrogen. Another route being pursued is the hydrogen hybrid heating system that combines a H2 boiler and heat pump e.g. trials at Port of Milford Haven.

The H2HEAT 100% H2-CHP developed by partner 2G will be the first real commercial scale H2-CHP.

The key innovations include:

- It is the first CHP to work with H2 stably, with high efficiency.

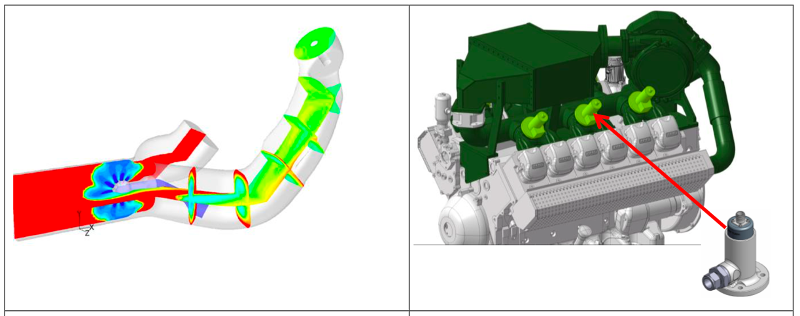

- Due to the fact that hydrogen has a very high detonation capacity, the mixture will take place inside the combustion chamber, so the gas will be injected through the Hoebiger injection valve, while the air will be compressed with the turbocharger. The process has to be very precise, therefore the injection valves will be electronically correlated with the cylinder head valves.

- It is essential to be able to control the production of electricity, and enable it quickly adapt to the consumer requirements. The 2G H2-CHP will be able to start, stop and work at part load. It will to be able to work in island mode and achieve the maximum load possible in the minimum time.

- The CHP from 2G can operate with varying levels of gas purity compared to fuel cells which require pure H2.

INNOVATIVE H2-CHP/ HEAT PUMP COMBINED SYSTEM

H2HEAT is leading the way in reducing emissions in industrial heat supply, where low-temperature heat (<100 °C) is in high demand.

Heat pumps are well suited to reducing emissions in the supply of low temperature (<100 °C) heat, which, according to the International Energy Agency (IEA), is the largest source of industrial heat demand today. A heat pump might typically have a Coefficient of Performance (COP) of 3-5 (or higher depending on the application), i.e. it can transfer 500 % more energy than it consumes. A high efficiency gas boiler might achieve a maximum of 95%. Therefore, the use of heat pumps instead of boilers is highly efficient and can contribute substantially to the carbon footprint reduction. Currently, most heat pumps in commercial systems are powered by conventional energy.

The H2HEAT concept is to combine the H2-CHP with the heat pump. Partner 2G will complete this integration and include it as part of their product roadmap. This has multiple benefits to CHUIMI hospital. Firstly, the direct use of the energy produced by the CHP from H2 will make the heat generated 100% green. Secondly, it avoids the necessity for CHUIMI of having to integrate the H2-CHP into its electrical system, saving costs. Thirdly, the high COP of the heat pump combined with the H2-CHP heat output will come close to supplying all of CHUIMI heat requirement.