Hybrid combinations of RE for H2 production are relatively nascent and certainly have not been trialled extensively in a real environment. Therefore the EMS and DSM required to cater electrically for such a complex mix is still relatively new. BIG HIT used a combination of wind and tidal RE. However, at peak it only produced 50t p.a H2. Likewise, digital simulation systems for planning and testing multiple RE combinations for H2 production are at development stage.

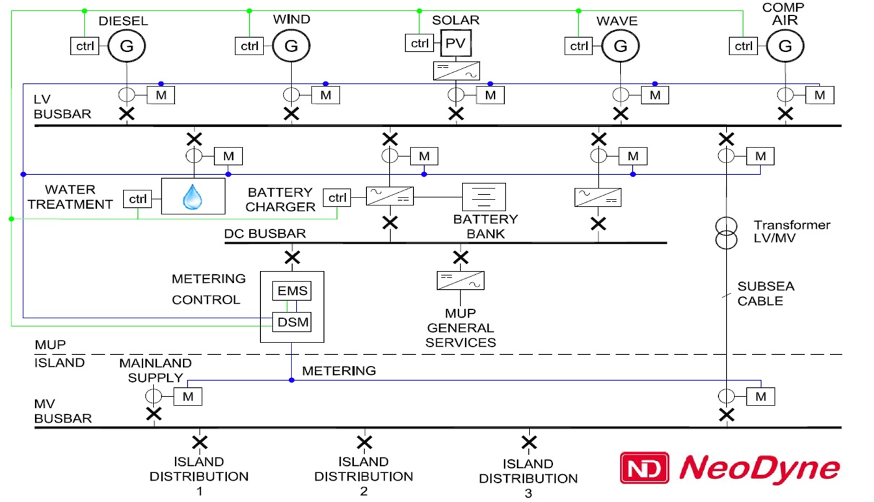

H2HEAT partner will develop a highly innovative smart digital system that will be capable of managing combined non-correlated multiple RE types and integrate with the H2 production via a sophisticated control system incorporating smart EMS, DSM and SCADA.

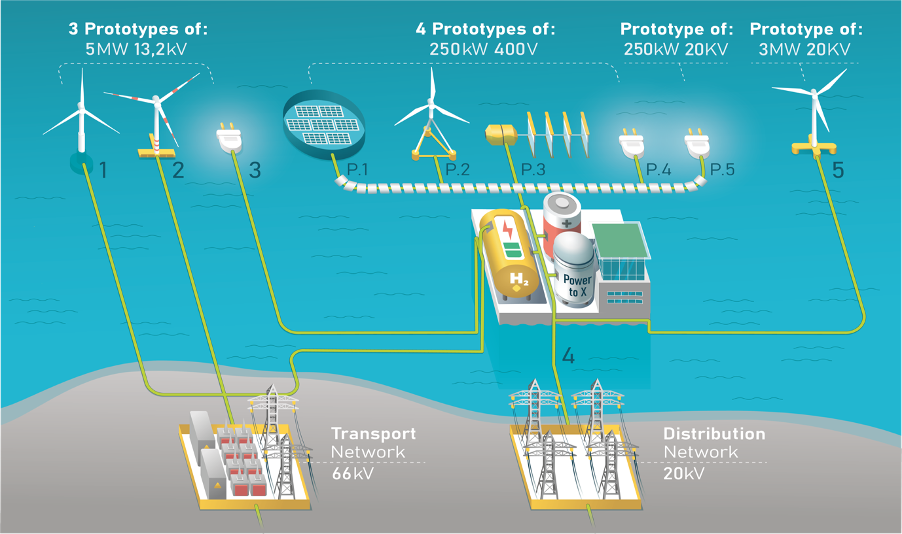

While H2HEAT will use OSW only, the control system will be future proofed to the PLOCAN vision for its research centre of multiple RE sources and types.

There are increasing numbers of H2 projects using electrolysers for conversion of RE. However, there are only a limited number based on islands. Surf ‘n’ Turf, the predecessor of BIG HIT encountered corrosion on the electrolyser due to the prevailing conditions on the Orkney Islands.

The Oyster project will investigate the feasibility of combining an OSW turbine directly with an electrolyser and transporting renewable hydrogen to shore. However, it is a scale trial only with no commercial end consumer, not post project continuity.

H2HEAT will locate the H2 production facility in the PLOCAN nearshore site. The choice of the onshore over the marine based RE equipment (Oyster) is to reduce maintenance cost and increase efficiency in operations, particularly for multiple RE sources. The H2HEAT electrolysis system that will be installed will have to operate efficiently under occasionally difficult nearshore conditions while requiring minimal maintenance and still meet performance targets.

Learning from such EU island projects as BIG HIT, H2HEAT will investigate:

- improved coating protection systems used on equipment e.g. from the Oil and Gas industry (NORSOK M501, C5),

- anti-corrosion material such as Xylan®.

- materials of construction e.g. Stainless steel minimum grade 316

- galvanic isolation use when considering dissimilar materials of construction if appropriate