H2Heat Positioning in terms of R&I Maturity and Technology Readiness Level – Part 1

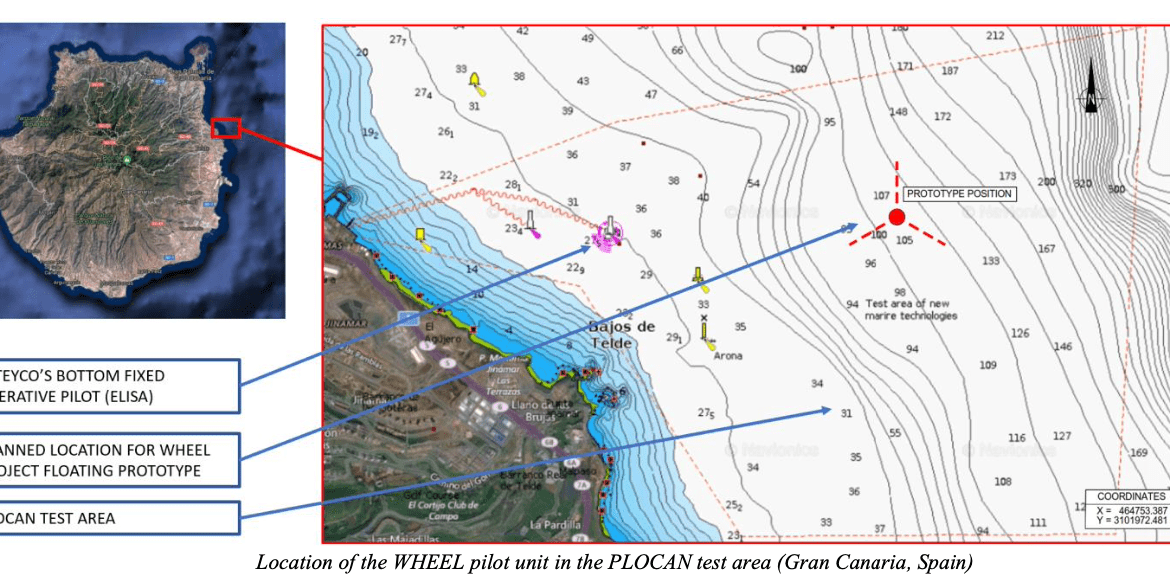

H2Heat Positioning in terms of R&I Maturity and Technology Readiness Level – Part 1 https://h2-heat.eu/wp-content/uploads/2023/09/Map-of-project-1-1024x475.png 1024 475 H2Heat Project https://h2-heat.eu/wp-content/uploads/2023/09/Map-of-project-1-1024x475.pngThe H2HEAT project is all about making green hydrogen for heating a practical reality. It’s not just about ideas; it’s about putting them into action. We’re taking the lab experiments and turning them into real-world solutions.

| Technology | TRL4 | TRL5 | TRL6 | TRL7 | TRL8 | TRL9 |

| OSW | Yes | Yes | ||||

| Electrolyser | Yes | Yes | ||||

| H2-CHP | Yes | Yes | Yes | |||

| Heat Pump | Yes | Yes | ||||

| H2 compression and storage | Yes | Yes | ||||

| EMS | Yes | Yes | Yes |

Ambition and progress beyond state of the art

H2HEAT will contribute substantially to advancing the concept of green H2 for heating (and O2) both in terms of “idea to application” and “lab to market“.

Electrolyser Advances

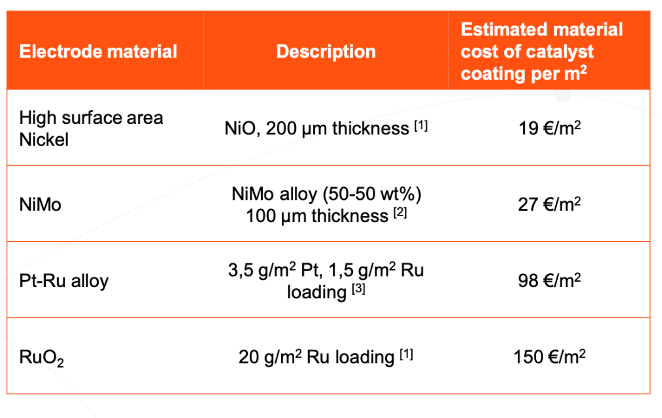

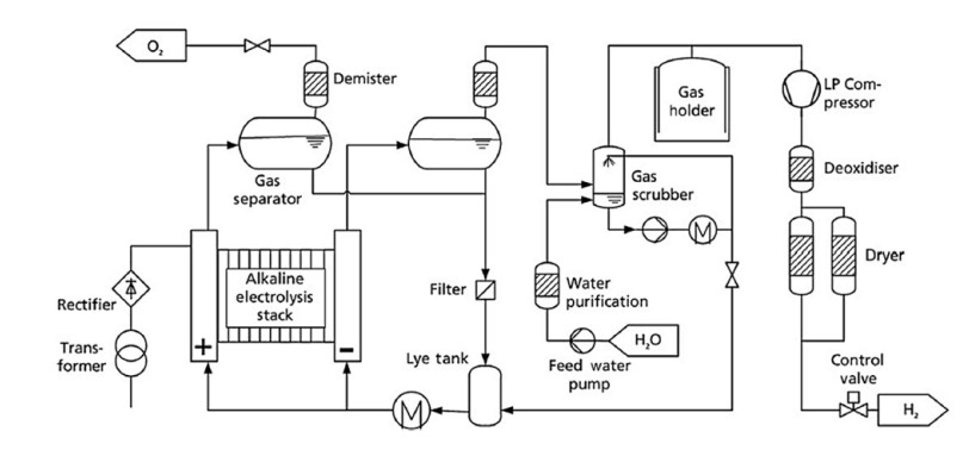

Alkaline based electrolysers are more mature when compared with proton (PEM) or anion (AEM) exchange membrane electrolysers. However, they typically employ expensive electrode precious metal materials resulting in cost inefficiencies and likely increasing future costs.

Stargate Hydrogen is developing advanced alkaline electrolysers based on nanoceramic active materials. The use of novel materials allows Stargate to achieve performance that is on par with widely used precious metal-based electrolysers (both PEM and precious metal-based alkaline), yet without the use of precious metals. It will be demonstrated that the materials that Stargate utilizes in its novel cells and stacks can achieve electric power consumption of 45 kWh/kg H2 at the high-efficiency operating point. Quantitatively, Stargate electrodes will demonstrate electrolysis current ≥50x higher than for IrO2 electrodes per EUR invested.

H2-CHP ADVANCES

There are currently no 100% H2-CHP installations in most European countries. There are none in the Canary Islands. An alternative are 100% H2 boilers, but they too at R&I stage. EU funded BIG HIT combined 12 5kW domestic H2 boilers to heat 2 schools. Progress is being made on blend-certified condensing boilers (typically 20% H2 with natural gas) which will eventually be replaced by pure hydrogen. Another route being pursued is the hydrogen hybrid heating system that combines a H2 boiler and heat pump e.g. trials at Port of Milford Haven.

The H2HEAT 100% H2-CHP developed by partner 2G will be the first real commercial scale H2-CHP.

The key innovations include:

- It is the first CHP to work with H2 stably, with high efficiency.

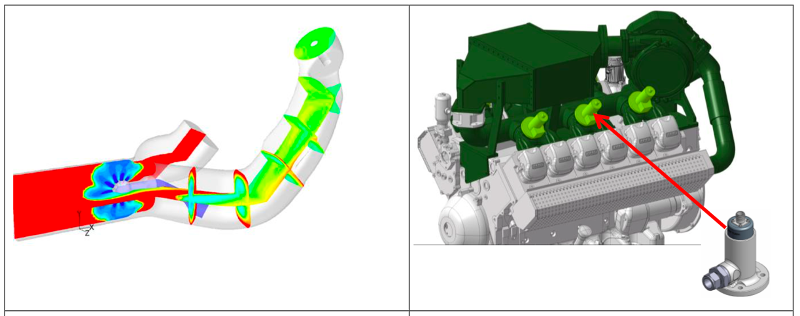

- Due to the fact that hydrogen has a very high detonation capacity, the mixture will take place inside the combustion chamber, so the gas will be injected through the Hoebiger injection valve, while the air will be compressed with the turbocharger. The process has to be very precise, therefore the injection valves will be electronically correlated with the cylinder head valves.

- It is essential to be able to control the production of electricity, and enable it quickly adapt to the consumer requirements. The 2G H2-CHP will be able to start, stop and work at part load. It will to be able to work in island mode and achieve the maximum load possible in the minimum time.

- The CHP from 2G can operate with varying levels of gas purity compared to fuel cells which require pure H2.